About KITO Armaturen GmbH

The brand name KITO® has been associated with flame arresters manufactured in Braun-

schweig, Germany for over 90 years. KITO Armaturen GmbH was originally born of Wilke-Werke AG many years ago. The latter was responsible for developing the KITO® trademark and brand itself from an abbreviation for the old expression Kiestopf (or common gravel pot).

We regard collaboration on the latest standardization as essential, and we keep our customers up to date at all times with the latest developments and ideas in safety technology through appropriate training measures and seminars.

The size of our company enables us to identify speedy and highly flexible solutions for our

customers’ needs. Special customer-specific designs are part of our expertise, as are rapid ap-provals for special flame arresters. Our delivery times are short and reliable, adjusted to suitthe requirements of our customers.

We regard our reputation as a reliable and trustworthy partner as a mark of our excellence.

Certification.

As a certified manufacturer of flame arresters and safety equipment, KITO® has a long-estab-lished QA system conforming to DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015. Our products also comply with European Directive 2014/34/EU, with individual products having specific certification. KITO® is regularly audited by a third party.

We are an approved manufacturer pursuant to the Pressure Equipment Directive (PED), working with vessel codes AD 2000 and DIN EN ISO 3834-2 (EN 729-2). TÜV North Systems, a notified body, monitors our certification as a welding company.

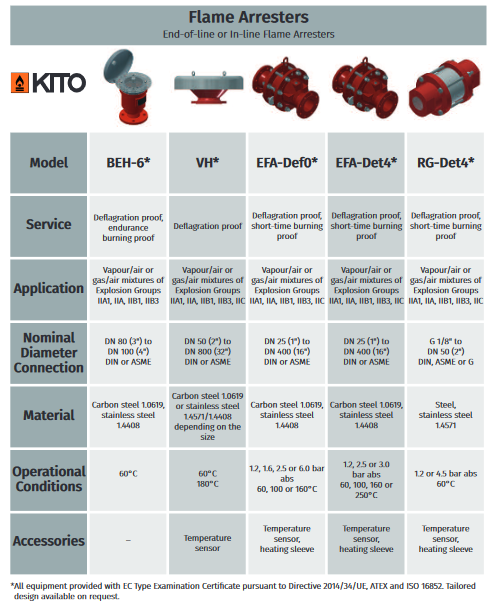

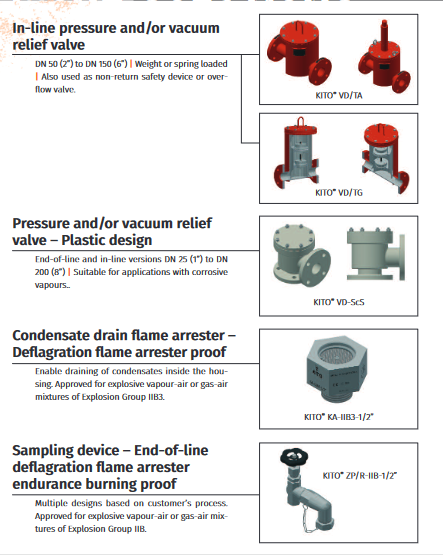

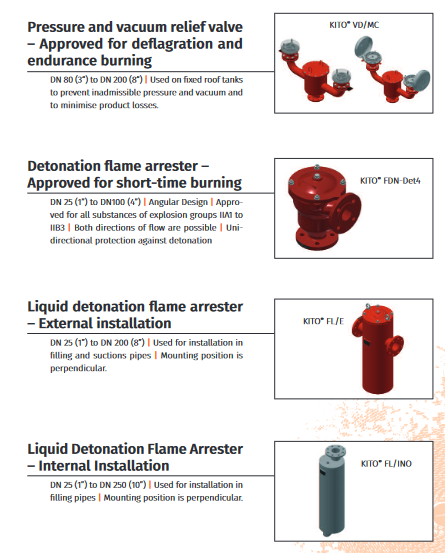

Flame Arresters

Flame arresters are devices fitted to the opening of an enclosure or connecting pipe work and

designed to allow flow but prevent flame transmission. They are commonly used to protect

tanks and installations from possible risks relating to the transport or storage of flammable

liquids and gases. Depending on the application, flame arrester may be installed as a single unit or as part of a system.

Flame arresters have no moving parts and consist of a housing and an element suitable for

installation in a pipeline, vent lines or process plants. All flame arresters designed and manufactured by KITO consist of layers of wound, corrugated

metal ribbons. Their principle depends on heat from the flame as it strives to travel through

narrow metal gaps. KITO® flame arresters and valves with integrated flame arresters conform to the Product Di-

rective 2014/34/EU of the European Union and bear the CE mark to indicate their conformity.

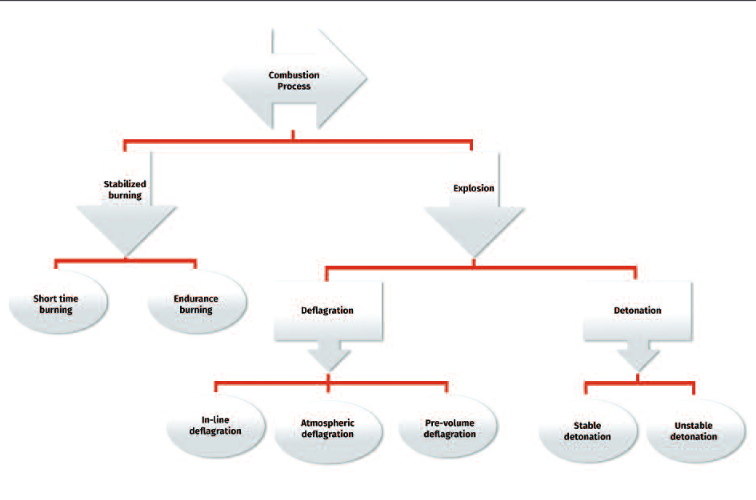

Combustion Processes

the explosion. Since explosive mixtures can burn in different ways, depending on the chemical

composition, pre-compression, geometric shape of the combustion chamber, flame speed and other factors, it is quite important to define the combustion process in order to select the most suitable flame arrester.

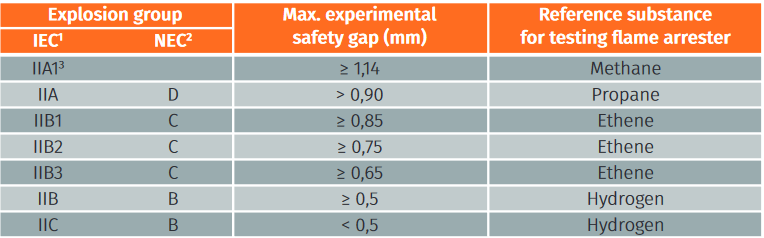

Explosion Group

Different gases react in a distinctive manner and have different flame propagation characteristics. For a simple classification and understanding, they are categorised according to their properties and hazard levels into explosion groups.

These explosion groups (or gas group) are defined based on the Maximum Experimental Safety

Gap (MESG). The Maximum Experimental Safe Gap (MESG) is expressed in mm and defined as the maximum gap between two flat surfaces, which prevents flame transmission for all concentrations of a respective flammable gas/air mixture propagating from an inner explosion chamber through a 25-mm long path into an outer explosion chamber.

The test conditions are standardized in IEC 60079-20-1

- IEC International Electric Code

- NEC National Electric Code

- In accordance with ISO 16852

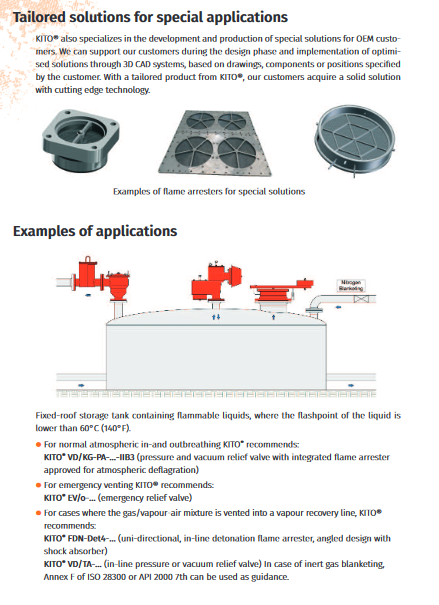

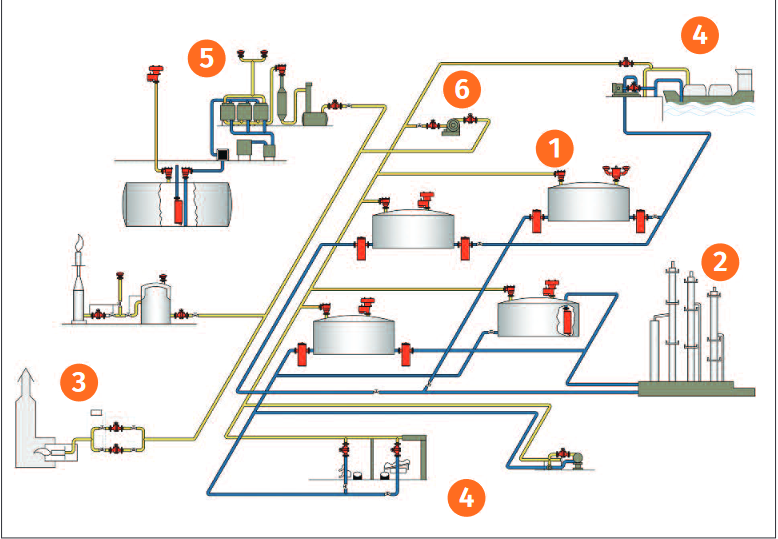

KITO ® Application – Industries Overview

- Tank farms

- Process plants

- Thermal treatment plants

- Loading and unloading process as part of logistics

- Vapour recovery units (VRU’s)

- Components as safety part of devices

- Protection of other plants – not illustrated

- Pharmaceutical

- Fertilisers & agro-chemicals

- Waste treatment

- Mining

- Food & beverages

- Bioethanol / Biodiesel

- Pulp & paper

- Equipment manufacturers